Zero-Speed Inertial Profiler Proves It Can Achieve Exceptional Results In Mississippi

During NCHRP 10-106 testing in Mississippi the SSI Zero-Speed Inertial Profiler exceeded expectations for data accuracy and repeatability on an AASHTO r56 certification track

(April 2022) SSI collected profile data under multiple conditions to replicate acceleration, deceleration, and stopping during a NCHRP data collection rodeo. The scenarios selected tested the accuracy and repeatability of the Zero-Speed Inertial Profiler under conditions which would disqualify traditional inertial profiling systems.

Watch a video demonstration of the SSI Zero-Speed upgrade here.

The SSI Zero-Speed inertial profiler uses multiple sensors to collect data over a range of 0-100 mph. This eliminates the collection speed floor and speed drop outs which introduce IRI error for project and network level roads. The error, which is compounded by the squaring the accelerometer drift over time, can exceed 30,000 in/mile with an elevation error in the profile of more than 20-feet. The Zero-Speed Inertial Profiler eliminates this noise and collects an accurate profile at any speed, even through stoppages.

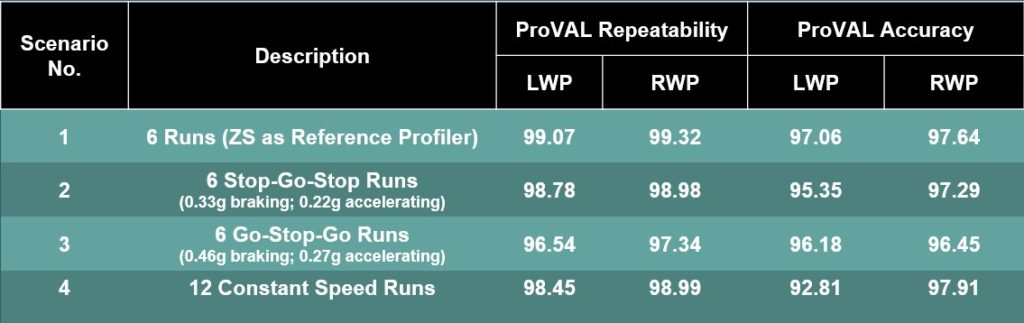

NCHRP 10-106 testing was created to learn more about the AASHTO r56 equipment certification. SSI took this opportunity to collect three stop-and-go scenarios plus additional constant speed runs with traditional inertial profilers. All runs were analyzed for repeatability and accuracy against SurPro reference data. The three scenarios were:

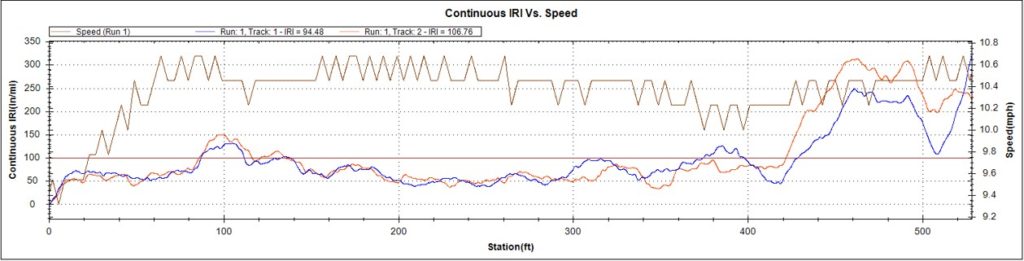

- Six low speed runs at 10mph for analyzing the Zero-Speed system as a reference device

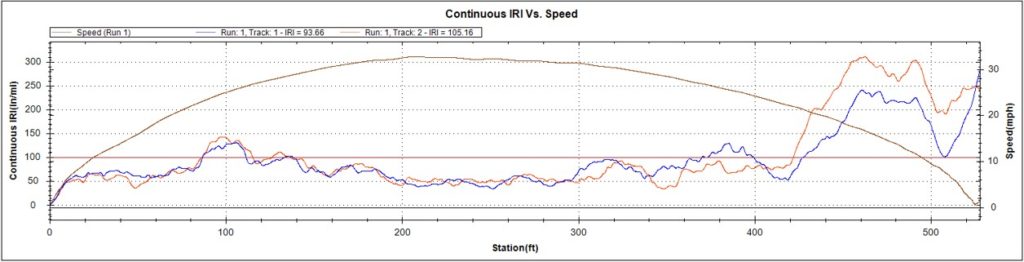

- Six Stop-Go-Stop runs. No Run up or run out. Accelerate to 30mph during collection

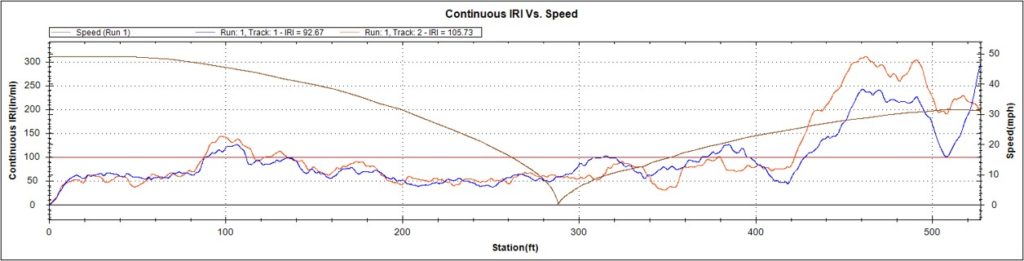

- Six Go-Stop-Go runs. Start collection at 50mph. Stop in middle of track. Accelerate to 30mph to end.

- Twelve constant speed traditional inertial profiler collections (six at 50mph, six and 30mph)

The Zero-Speed device achieved a passing certification score under AASHTO r56 for each scenario. The requirements for a compliant AASHTO r56 inertial profiler are 92% repeatability and 90% accuracy.

The fourth constant speed scenario was collected in the left wheel path (LWP) on the second day of testing when the SurPro reference data was collected on the first day. The inertial profilers and the Zero-Speed had IRI values of ~90 in/mile where the SurPro had a reference IRI of 94 in/mile. The surface may have changed which may explain the discrepancy between the LWP accuracy and the first day right wheel path (RWP) accuracy of almost 98%. This may highlight the importance of collecting reference data at the same time or as close to the time of the certification.

Zero-Speed Profiler as a Reference Device

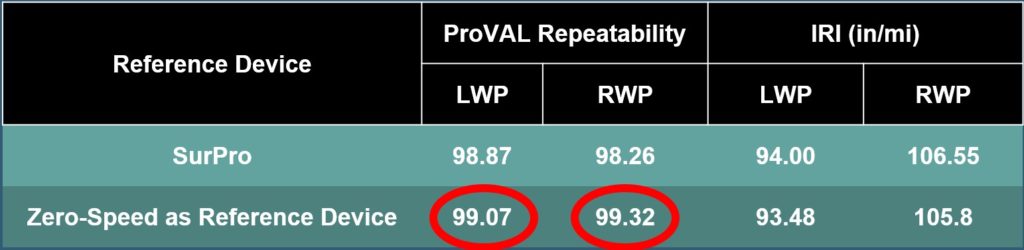

For a device to be considered a “reference device” the system must have three runs that are at least 98% repeatable against itself. Most DOT certification tracks will make multiple runs in each wheelpath with their walking reference device and compare them for repeatability to confirm the runs are similar to each other. Repeatability in ProVal is a function of profile amplitude and trends. It considers more than the ride value number so that the elevation profile is the driving comparison metric.

The SSI Zero-Speed device achieved reference level repeatability and introduced a concept of using the Zero-Speed device as a faster way to collect baseline reference profiles for certification tracks. More data is required to progress this methodology, but the data for the Zero-Speed as a reference device was proven on the Mississippi track. The benefit of using the Zero-Speed system as a reference is the speed of collection; it may reduce reference collection time by an order of 15. The Zero-Speed data was collected at 10mph (15 feet/second) compared to a walking profiler which usually collects under 2 feet/second. Plus, the Zero-Speed profiler is collecting data in both wheelpaths and the operator doesn’t have to walk back to the start of the track.

The results of the Zero-Speed repeatability and the SurPro repeatability are below. The SSI Zero-Speed Inertial Profiler actually outperformed the walking speed SurPro device. This could be related to multiple factors:

- Walking devices capture data over longer periods of time where the surface can change

- The SSI Zero-Speed system cancels vehicle motion and dynamics, where walking reference devices depend on a steady hand and constant speed to reduce noise introduced into the inclinometer, laser, or distance sampling encoder. Since the Zero-Speed cancels out more vehicle dynamics, the susceptibility of the Zero-Speed system to operator induced error is less likely.

This testing has proven the SSI Zero-Speed Inertial Profiler is a compliant method of collection data throughout the speed range of 0-100mph and through stoppages. The Zero-Speed system can also be used to collect data without run up or run out distance; a highlight for tightly constrained projects like airfield paving.

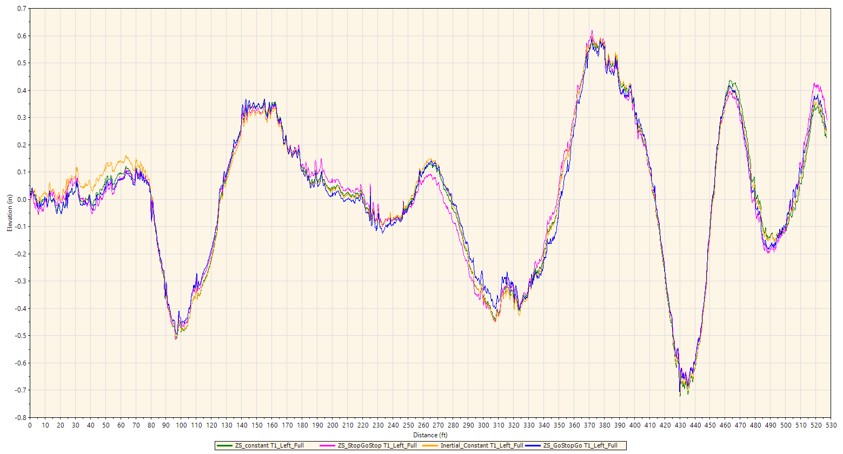

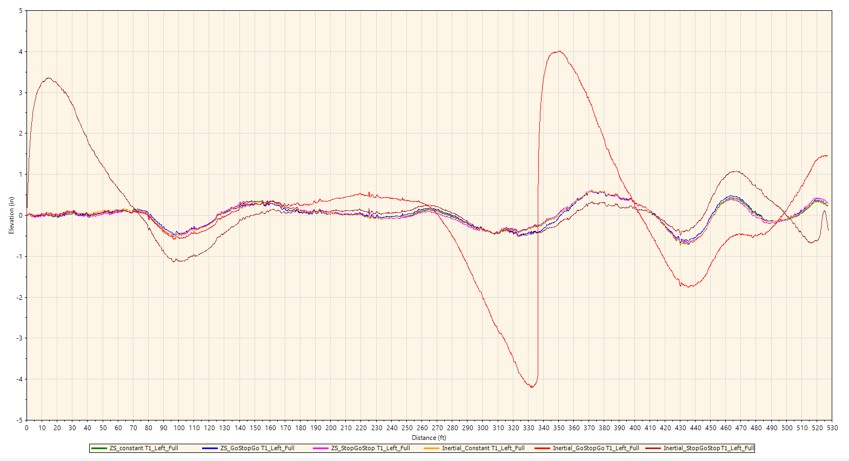

Plot of Zero-Speed Profile Data Paired with Constant Speed Runs

Plot of Traditional Inertial Profiler Runs with Accelerometer Drift From Low Speeds

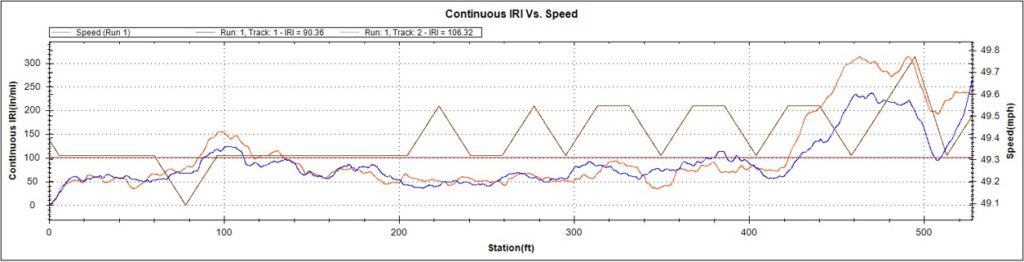

Scenario 1 Plot vs Speed: Zero-Speed Reference Profiler Collection

Scenario 2 Plot vs Speed: Stop-Go-Stop Collection (No Run Up or Run Out)

Scenario 3 Plot vs Speed: Go-Stop-Go Collection

Scenario 4 Plot vs Speed – Constant Speed Zero-Speed System Collection