Edge Slump Measurement Added to SSI Profiler Software

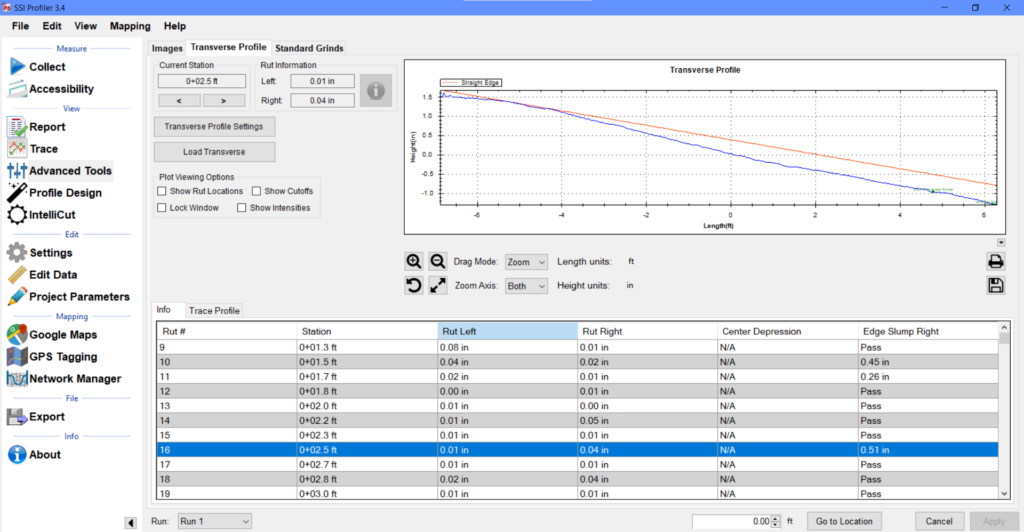

SSI Profiler software can now analyze transverse profiles for edge slump for slip-form concrete paving

A concrete contractor and long time SSI profiler user asked us in late 2022 if we could measure edge slump on concrete pavements. After reviewing their project specifications and ideal system configuration we determined it was possible to replicate the manual straightedge measurement. Edge slump analysis options were added to the SSI Profiler software for use with SSI transverse profiling systems. The contractor now uses a CS8750 Survey Profiler mounted to a Polaris Ranger to measure 3D survey elevations, edge slump, and pavement smoothness with a Zero-Speed profiler. All of these features are included in one collection system and one software.

What is Edge Slump?

Slump is commonly known as the plastic deformation, or fluidity, of wet concrete. Contractors and quality control labs perform ASTM C143 slump tests with a slump cone throughout paving. While slump and edge slump are related, they are tested at different times with different tools. Edge slump is the deformation on the edge of a concrete panel during the slip-form paving process. Edge slump measurements are captured with a 12-foot straightedge once the concrete can support foot traffic.

The FAA specification section 2.1.2.1. requires that no more than 15% of the measured edge slumps be greater than 6mm (1/4″), while no measurement can exceed 9mm (3/8″). The straightedge testing must be completed at a 5-foot spacing along the edge of pavement. If most areas are in compliance, the spacing may be increased to 10-feet until a non-compliant section is measured.

The Manual Measurement Problem

Straightedge testing requires hours of dedicated labor. A simple example is for every 1,000-feet of paving there can be 2,000 feet of open edge. If testing is performed every 5-feet there are 400 straightedge measurements to record. If it takes 2-minutes to measure and record each location, that is over 13 hours of straightedging. Some agencies have required contractors to submit edge slump reports within 24-hours of paving, before they were allowed to move on to a new paving section. A contractor asked SSI if any equipment could speed up their collection process for edge slump and edge deformation.

SSI’s Solution

The goal for this development has been to mimic the straightedge measurements. It was determined to use either SSI CS9500 or CS8750 transverse profiling platforms to gather transverse profiles at least 12-feet long near the edge of pavement.

These SSI systems use 5 or 6 laser sensors to measure elevations. The sensors are combined to capture full 12-foot transverse profiles at the same time as a seamless beam across the pavement. Unlike LiDAR which would have a zig-zag motion across the pavement surface. By collecting a seamless transverse profile, the user can be confident that the laser elevations are measuring the same points that the straightedge will be placed on.

The SSI transverse profiling systems use multiple lasers, each with about 1280 points of measurement. Each complete transverse profile can be sampled from 6,400 to 7,500 laser points. Typically, the sampling interval for SSI transverse profiling systems is 2-inches longitudinally and 0.5-inch transverse at a top speed over 55mph. The collected data is dense and accurate with the lasers able to verify under AASHTO r56 for 0.01-inch accuracy.

The additional features of the SSI profiling system include AASHTO r56 and ASTM E950 compliant inertial profiler, Zero-Speed inertial profiler compatibility, and 2D or 3D survey point clouds. The Zero-Speed inertial profiler uses the laser and an INS unit to allow for smoothness measurements with zero run up or run out and complete stops without losing data.

Edge slump data can be collected while driving the Polaris Ranger and any speed. For the Ranger 570, the maximum speed is about 50mph. The automatic reporting within the software allows for rapid results as soon as the collection is completed.

Measurement Correlations

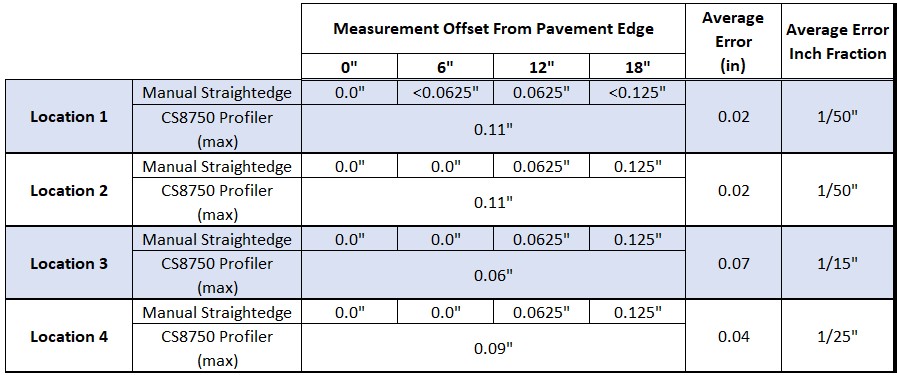

The Contractor manually recorded measurements to verify the SSI CS8750 edge slump reporting. The Contractor recorded four locations within the 18-inch edge window at 0, 6, 12, and 18-inches. These locations were compared to the maximum edge slump report from the CS8750.

The results were errors less than the resolution of the manual straightedge being used by the Contractor. The manual straightedge method cannot give an absolute recorded value. The straightedge method uses gauge blocks to test the gaps at each of the four locations from the edge of pavement. With a laser accuracy less than 0.01-inch, the CS8750 can simulate the placement of a straightedge with high accuracy and repeatability.

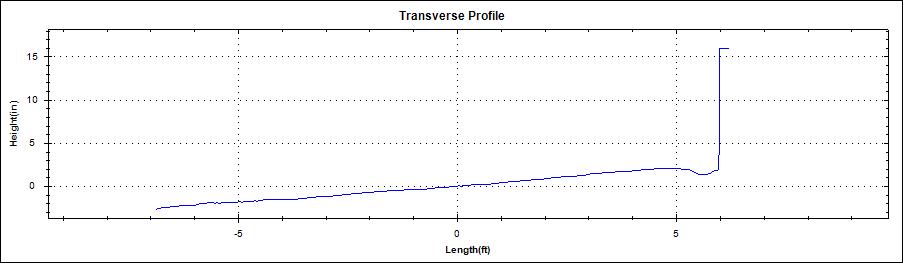

An example of a transverse profile collected on top of the new panel. The edge dropoff is defined, but the vertical face is partially blocked from the laser sensor which is mounted to the vehicle sitting on top of the new panel.

Edge Deformation

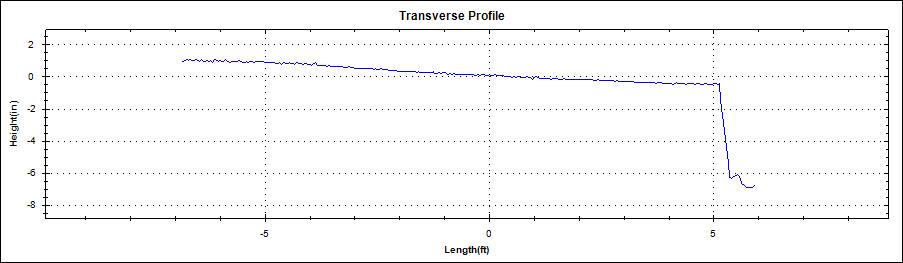

While the edge slump data is collected on top of the panel, the edge deformation can be measured by driving on grade adjacent to the panel. Stage 2 of the verification was collecting data for comparison of the edge deformation.

The lasers of the CS8750 can measure to the top of the panel and report simulated longitudinal and vertical straightedge results. The longitudinal straightedge on the top edge, center of face, plumbness of the vertical face, and vertical offset are all reported from one pass of the CS8750.