Monitor Your Paving Crew To Track Smoothness Defects

Hardware

- Single or Dual Laser System

- Exact Same System for Asphalt or Concrete Pavers

- Sensors are mounted over 4-feet (50-inches) above the pavement surface

- Sensors do not require additional cooling equipment when measuring asphalt pavements

- Computer and electronics are portable and easily removed from paver

- Military grade IMU

- Accurate positioning and high satellite count

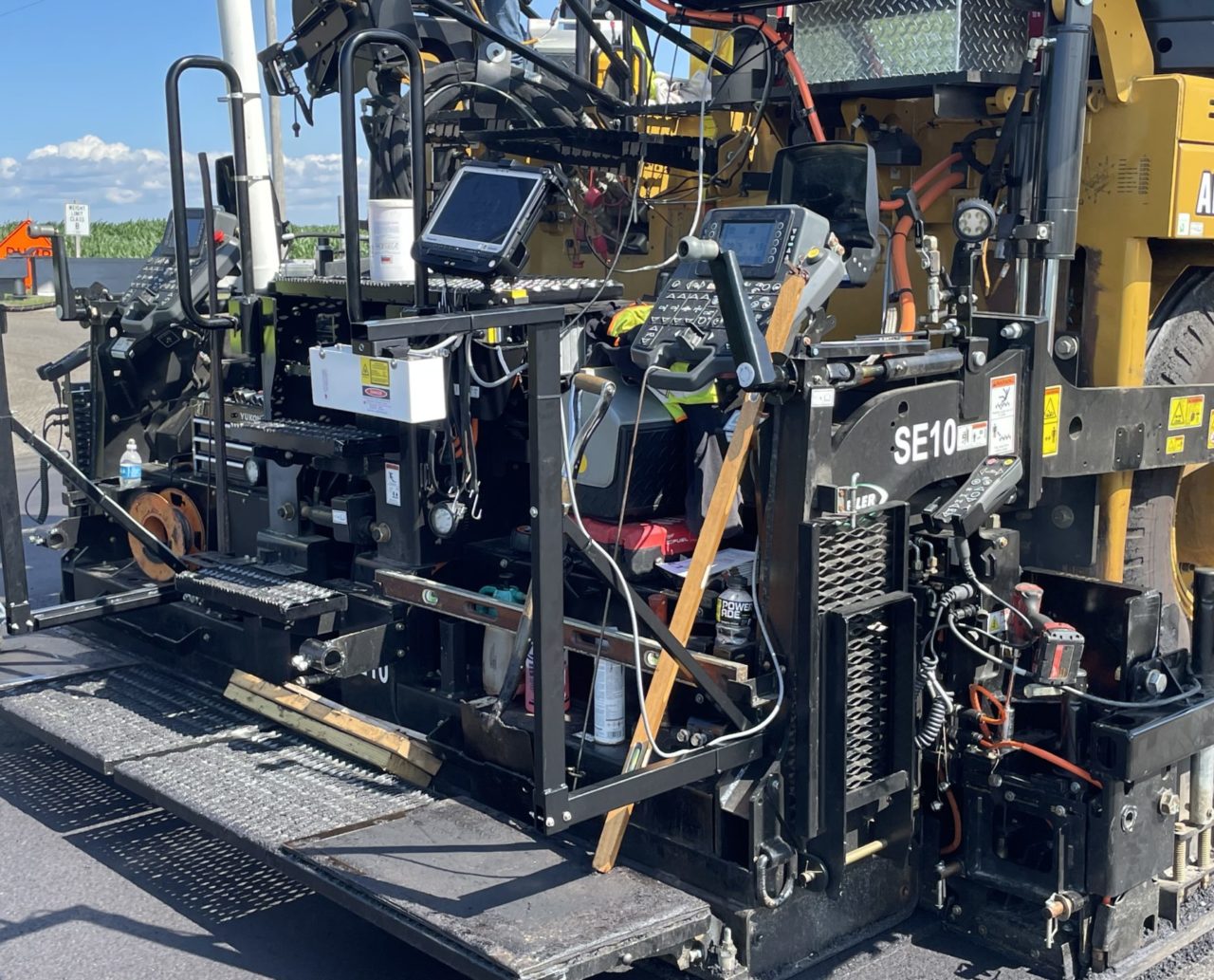

Asphalt Paver Configuration

Concrete Paver Configuration

Software

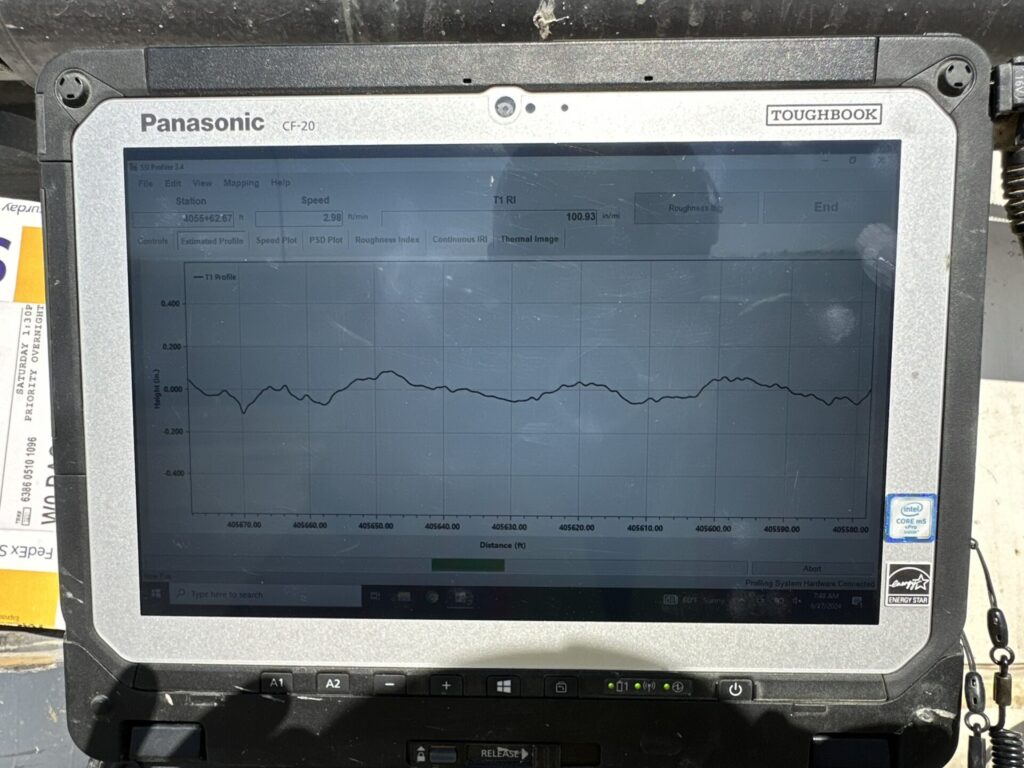

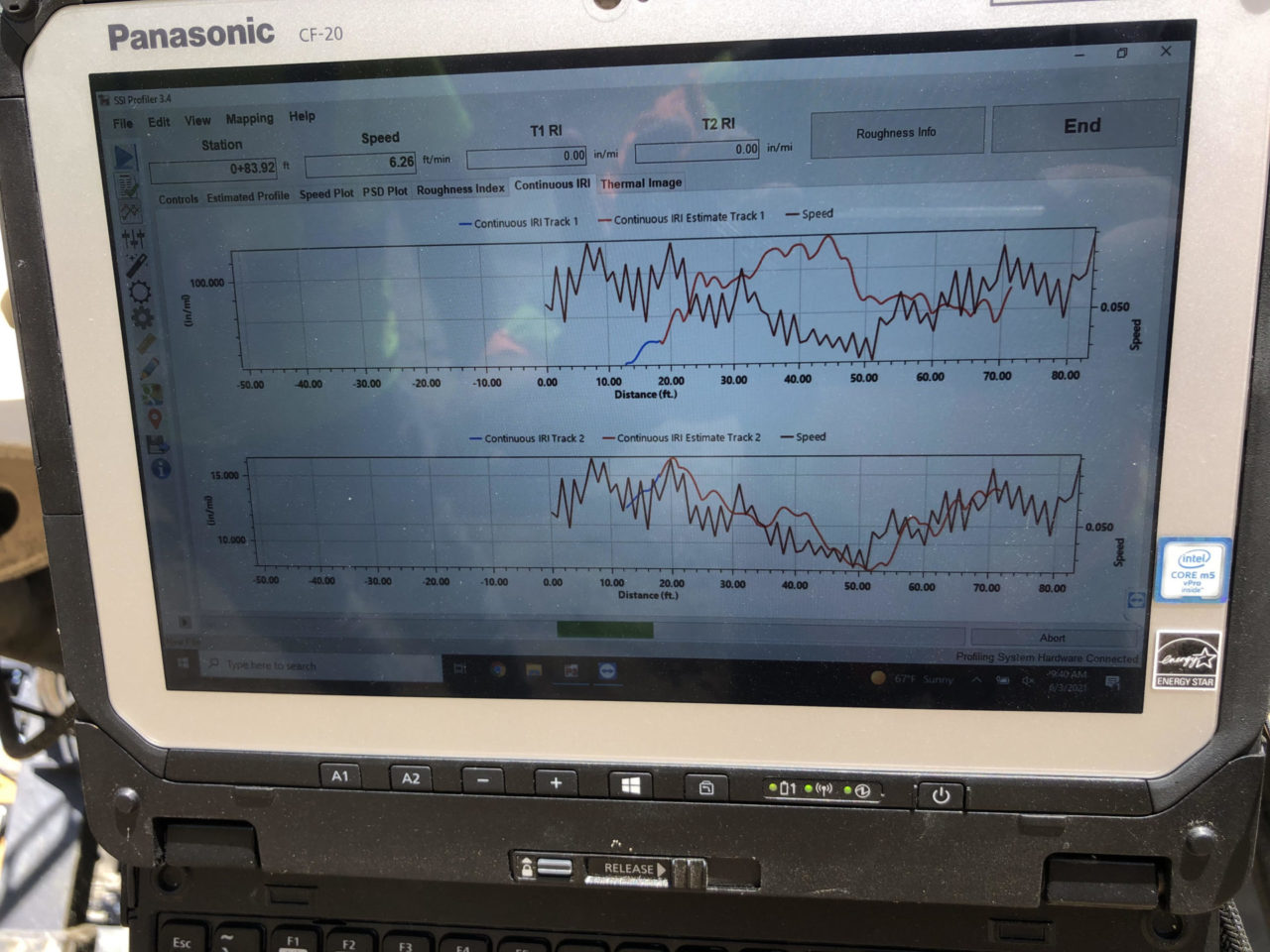

- View IRI and speed plots in real time

- View PSD Plot in real time

- View Areas of Localized Roughness (ALR) in real time

- Collection screen is color coded for roughness events (bumps/dips)

- Operator can add events with hot keys

- Automatic events based on project conditions

- Calibrate and collect data within SSI Profiler software

- Calibrations are for distance and leveling

- Simple and concise reports for ride values

- ProVal compatible data exports

- Export data to PDF, Excel, PPF, ERD, Google Earth

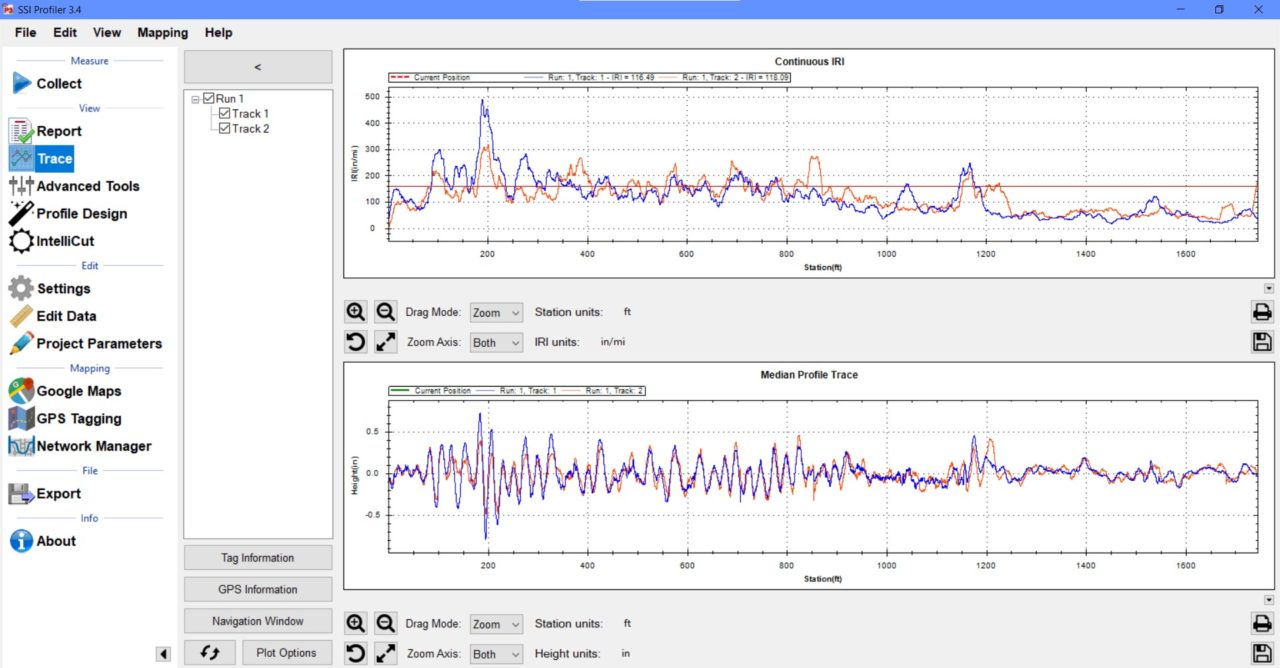

SSI Onpaver Matches The Hardened Profiles of Inertial Profilers

Verified by Inertial Systems

The CS7800 Onpaver Profiler accurately matches the IRI profiles collected with the inertial profiler on a hardened surface. The CS7800 collects data to be analyzed under IRI, MRI, HRI, or localized roughness.

Hardware

CS7800 Onpaver Lasers

- 40-50 inch standoff (102-127 cm)

- 5KHz wide beam Class IIIB lasers

- Linearity (Z): 0.05% of MR

- Resolution (Z): 0.154 mm – 0.56 mm

- One laser per wheelpath

Optical Encoder

Wheel mounted high resolution optical encoder for fine increment distance measurement.

- Longitudinal distance accurate to 0.1%

INS Receiver

Multiple GPS receivers are available from SSI. For Onpaver systems, the GPS is embedded with the INS system for added satellite constellations, reception reliability and accuracy.

- Embedded GPS, Glonass, Beidou, Galileo constellations optional

- Over 35 satellites available

- Up to 100Hz Sampling

- PPK Horizontal Accuracy: 1 cm

- PPK Vertical Accuracy: 2.5cm

- IMU Pitch and Roll Accuracy: 0.02 degrees

- IMU Heading Accuracy: 0.1 degree

- IMU Velocity Accuracy: 0.02 m/sec HRMS

- Satellite Signals: L1/L2

- Cold Start, Time to First Fix: <60 seconds

- Dynamic Range (Gyro, Accelerometer): 125˚/s, 8g

- Bias Instability (Gyro, Accelerometer): 0.8˚/h, 3.2µg

Software

- Collection speed 0-15 mph

- Display 1 or 2 wheelpaths in real time

- View localized roughness, fixed interval, PSD plot and thermal image in real time

- Auto-event notes for speed changes

- Color-coded screen for bumps and dips forming

- Calibrate through program prompts user can easily follow

- Startup time is <10 minutes

- Export PRO, PPF, ERD, Excel, PDF

- Reports IRI, MRI, HRI, PRI, RN, and Localized Roughness (with adjustable bump and dip templates)

- Instant test results and viewing of profile traces and reports

- Outputs longitudinal profile, elevation data, slope, simulated profilograph, raw strip trace, ERD/PPF (for ProVal), and PRO formats

- Multiple trace reporting allows cross-surface analysis of parallel profile traces (patented by SSI)

- Append data to existing files for comparison of original surface condition with corrected surface

- Profile reports and traces available on-screen, in PDF images, Excel (templates supplied), hard copy print out, or electronic formats

- Colorized traces and highlights of bonus/penalty profile areas

- Encrypted raw data for infinite reanalysis with variable parameters

- Data infinitely rewritable with variable analysis parameters (English or Metric units, profile indexes, data filters, localized roughness).

Troubleshooting

- Embedded PDF user manual in software

- Send Feedback or report issues to SSI staff directly

- Real time diagnostics monitor system health and ease support

- Desktop license supplied for viewing, analyzing, and printing data

- Software updates by self-executing internet download

- On-site customer training and support worldwide